Using casting process simulation to improve castings’ environmental footprint

Written by: Håkan Fransson, Technical Simulation Manager

When a casting part is produced, a high amount of energy is generated since we need to melt the metal and then keep it at a high temperature during its filling into the mold cavity. This means that the production of a casting results in a big environmental footprint and high CO2 emissions during its manufacturing process. This footprint is inevitable but can be reduced by changing how you cast it. This article will be focused on the possibilities to improve this and the use of casting process simulation to support the work.

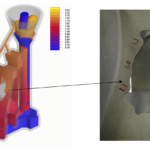

Proof of how accurate simulations can be in terms of cold flows.

Possible improvements on the casting and the manufacturing process

There are a number of areas around the castings and its process that actually can be improved and here is a list of them:

• Producing more thin-walled castings. This saves weight and energy both during the casting process but also in the final product.

• Yield improvement. By reducing the amount of liquid metal needed to produce the casting, you save poured amount of metal, energy and reduce CO2 emissions.

• Optimize the casting parameters so a lower casting temperature could be used which saves energy and reduces CO2 emissions.

• Optimize your gating system technology without using for example filters which saves cost.

• Optimize your feeding system and the need for feeders by also optimizing the casting. Less need for exothermic feeders and less poured material give lower cost, reduced material consumption, reduced energy consumption and lower CO2 emissions.

• Reduce defects in castings. Simulated castings give lower scrap rate which results in lower cost, lower energy consumption, material need and less impact on the environment.

Our casting process simulation system, NovaFlow&Solid, supports the creativity to develop better castings and more efficient gating and feeding systems. It costs much less to make the errors in the computer and you can try new things without jeopardizing the production.

How NovaFlow&Solid can support the hunt for reduced environmental footprint:

With NovaFlow&Solid you get accurate cold flow predictions. This helps you to see where the limit goes for wall thickness but also to test different ways to push this limit downwards by testing different ways to pour the part.

On the other hand, NovaFlow&Solid can also find the lowest temperature that can be used to fill the part. If using a lower temperature, the overheating of the melt could be less and so could the melt holding temperature. This all results in lower energy consumption and less CO2 emissions.

The shrinkage prediction in NovaFlow&Solid can give you the ability to see how big the feeders really must be, and you can also test different combinations of feeders to get the optimum yield. Casting yield = casting weight/ (casting weight + feeder weight + gating system weight) x 100 = x %

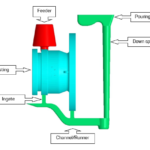

The velocity prediction in NovaFlow&Solid during filling makes it possible to verify the design of a gating system. A classic approach is the ratio 1:2:4 meaning that the area of the channel should be twice the area of the down sprue and the ingate should have twice the area of the channel. The choke in the down sprue should be at the bottom end. All made in order to achieve a turbulence free filling with an ingate speed of less than 0.5 m/s.

Good Guys’ Index

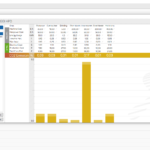

In combination with NovaFlow&Solid, you can use our GGI (Good Guys’ Index) program that helps you become greener. GGI calculates your yield and yield improvement. It also calculates the energy used to produce the castings and the CO2 emission that the casting process generates. The GGI communicates with NovaFlow&Solid but you can also edit many values in order to see how a change of the gating or feeding system will influence. You can also check the difference in CO2 emissions by changing energy source. In the latest version you can also take into account the surrounding processes to manufacture the casting with our new Process Editor:

The Good Guys’ Index calculates the costs for producing the casting which means that you can also use GGI as a cost estimator. It is fully adaptable for different materials and processes and we have made templates for gravity, HPD and investment casting. GGI can also be used completely stand-alone and you can manually input all the necessary values to make the calculation.

Correct usage of a good casting process simulation system combined with GGI can truly assist you in reducing the environmental footprint and make your foundry greener.

At NovaCast, we have a slogan “Every casting counts™” which means that you should be careful with every casting and make sure that you give each casting the best possibility to be improved. I also think that we should have the slogan of saying every kilogram counts as well as every kilowatt counts. The best resource is the one you did not have to use.