Chilling Fact: You Can Save Money by Thermal Analysis

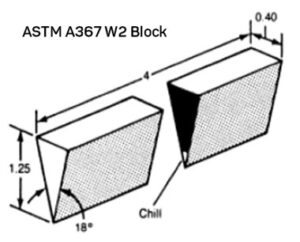

One very important effect of changing characteristics within the molten iron during induction furnace melting, revealed by thermal analysis, is the chill tendency. This means the cast iron is likely to form iron carbides during solidification, instead of graphite, as the stable form for carbon in ferrous alloys. Traditionally, chill tendency is evaluated according to the ASTM A367 standard.

Figure 1. ASTM A 367 W2 Block for determination of chill depth, [1]

Kubick et al. stated that increasing both superheating temperature and holding time decreases nodule count and increases chill depth as well as a higher inoculating temperature and longer holding time after inoculation. They also found that chilling tendency increases as nodularity decreases, [2].

Moreover, observations from ATAS® Verifier 4.0 (predecessor of ATAS MetStar) indicate that, the highest eutectic lower temperature (TElow), lowest chill depth and lowest percentage of shrinkage porosity, were recorder for lanthanum-bearing MgFeSi alloy in ladle treatment process, suggesting the strongest defiance against chill and shrinkage formation, [3].

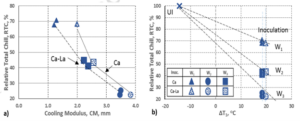

Riposan et al. reported that for inoculated cast irons, carbides formation incidence can be expressed by the relative total chill parameter (RTC). Speaking of that, it was stated that decrease of the solidification cooling rate by increasing the cooling modulus will lead to decrease of the carbide formation incidence. Moreover, in Figure 2. is illustrated how important inoculation process and a proper inoculant can be in order to control chill tendency. Finally, it was concluded that lower under-cooling at the beginning of the eutectic reaction is obtained with inoculated samples, inoculation leads to lower values of eutectic recalescence which directly means the higher low eutectic temperature (TElow) and significantly lower possibility of chill formation, [4].

Figure 2. Relative total chill RTC (a) and relationship RTC – ΔT11 (b), [4]

Our good friends at Torrance Casting (USA) performed tests by pouring molten iron into the cold box cores with wedge-shaped cavities. The samples are then broken to reveal the fracture surfaces and measured for the chill depths. The chill depth is used as an indicator for the chilling tendency. However, the test requires time for sample to cool down to dull red before quenching; therefore, the test is usually conducted along with the pouring of the castings. However, the thermal analysis is the faster test which can be used as a preventive or proactive measure.

The advantage of thermal analysis is to have high quality information on the foundry floor within minutes of sampling and reducing the turnaround time of the laboratory to just a few minutes. While other methods, such as the wedge test and spectrographic chemical analysis, deliver useful information, cooling curve analysis (CCA) can provide a more complete insight into the dynamic changes occurring upon melting and treatment of the molten casting alloys.

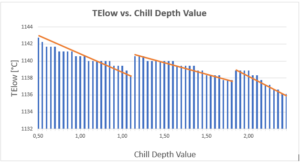

The effective solution to avoid chill wedge tests is to control the lower eutectic temperature in ATAS MetStar, also known as a TElow. This temperature represents lowest melting point and depends mainly on the nucleation status. A low temperature indicates that the nucleation status is less effective.

A too low value is often obtained if the oxygen content or the number of nucleation sites is too low. It is important to achieve a charge composition where TElow remains at a high level at least 30 minutes after the melt is ready.

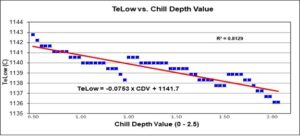

According to our satisfied customer, which actually proved this statement, a high value of TElow is normally better, higher than 1145 °C. It reflects the nucleation status of the melt. Low values increase chill and macro-shrink.

Figure 3. Diagram of TElow vs. Chill depth value

The diagram in figures 3 and 4 indicate the correlation between the lower eutectic temperature and chill depth value. As it can be seen, with decreasing the TElow, the chill depth value is increasing which directly increase the chill tendency.

Figure 4. Correlation between TElow vs. Chill depth value

As a conclusion, it can be said that the TElow is inversely proportional to chill tendency, which means that keeping high values of lower eutectic temperature will prevent the chill formation.

As a result of controlling the TElow temperature with ATAS MetStar (instead of chill depth inspection), there is several benefits:

– Cost reduction (not producing coldbox cores for tests)

– Increase of production (one coldbox core machine more for production – better efficiency)

– Quality issues within the testing procedure of chill depth with wedge testing procedure

– Shorter time necessarily to obtain results and confirm the melt quality

– By this TElow control, at the same time, you are controlling the inoculation status of your melt

– With ATAS test, the results can be quantified sharply rather than leaving it to the subjective representation of the chill test by the operator

– Getting TElow reading allows ATAS MetStar to be proactive with suggestion for amount of inoculation addition needed to keep TElow high (chill free) in the molds.

1ΔT1 = TEU2 – Tmst3, under-cooling at the beginning of eutectic reaction, referring to the lowest eutectic temperature,

2TEU = the lowest temperature of eutectic reaction,

3Tmst = metastable (carbidic) temperature, [4].

Reference(s):

- “Solidification kinetics in grey iron”,NovaCast Foundry Solutions AB, Sweden.

- J. Kubick, A. Javaid, and F. J. Bradley, “An Investigation of the Effect of Carbon, Silicon, Sulfur, and Phosphorus on Solidification Characteristics and Chill Tendency of Gray Iron. Part II: Chill Tendency”, Transactions of the American Foundrymen’s Society, vol. 105, pp. 579-586, 1997.

- Skaland, “A New Method for Chill and Shrinkage Control in Ladle Treated Ductile Iron”, Elkem Foundry Products, Kristiansand, Norway, Keith Millis Symposium on Ductile Cast Iron, 2003.

- Stefan, M. Chisamera, I. Riposan, “Chill sensitiveness and thermal analysis parameters relationship in hypoeutectic, Ca and Ca-La inoculated commercial grey cast irons”, POLITEHNICA University of Bucharest, Materials Science and Engineering Faculty, Bucharest, Romania, 2020.