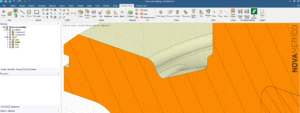

NovaMethod

Simplify your methoding. With NovaMethod you are able to easily create and edit your 3D model before simulating the casting detail. NovaMethod works perfectly as a preprocessor to our simulation software, NovaFlow&Solid and NovaOne, but can also be used independently.

Streamlined for the foundry industry.

NovaMethod is designed to meet the requirements you have on your preparation tools in your foundry. Whether it involves simply removing holes, creating new concepts from scratch or optimizing existing models, NovaMethod removes a common bottleneck and allows foundry men or women to focus on developing the casting. By putting simulation users in control of geometry, CAE can drive product development to optimize models before CAD and validate results post-CAD.

The perfect addition to your simulation solution.

NovaMethod is an optional module to NovaFlow&Solid and NovaOne as a part of efficient casting development tools. NovaMethod helps you optimize CAD models for input into NovaFlow&Solid either in STL or STEP format. You can perform geometry fixing as stitch faces, remove gaps and check and correct missing surfaces for solid modeling. Comprehensive STL fixing tool for simulation, as well as for 3D scanning or 3D printing.

With NovaMethod, you will get a geometry preparation tool designed to solve typical simulation related problems and interact with NovaFlow&Solid and NovaOne.

Not just a foundry CAD system.

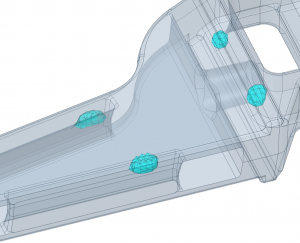

NovaMethod’s 3D modeling technology changes the way you think about working with 3D models because it lets you focus on your design without the complexity of traditional systems. For example, you can re-use data without planning and remix geometry from other designs, even those created in CAD systems. You can take a design where it needs to go, regardless of how it was built or in which system it was created.

NovaMethod can help you make fast re-runs of a simulation and change the design without contacting other resources or resorting to traditional CAD.

With NovaMethod, it’s possible to open CAD models from systems such as Pro/ENGINEER, CATIA, SolidWorks, Creo 3.0 and NX etc. Can can also repair poor quality geometry created by old CAD systems and surface modelers.

Learn more about our other modules for NovaFlow&Solid: