NovaCastCAD

NovaCastCAD is a revolutionary design optimization solution built for foundries, casting engineers, and product designers. It helps you work faster, optimize geometry for better solidification, and deliver high-quality castings from the start. With GPU-accelerated speed, smart automation, and powerful design tools, you reduce lead times, avoid trial-and-error, and make smarter decisions with greater confidence.

Built for the Future of Casting Design

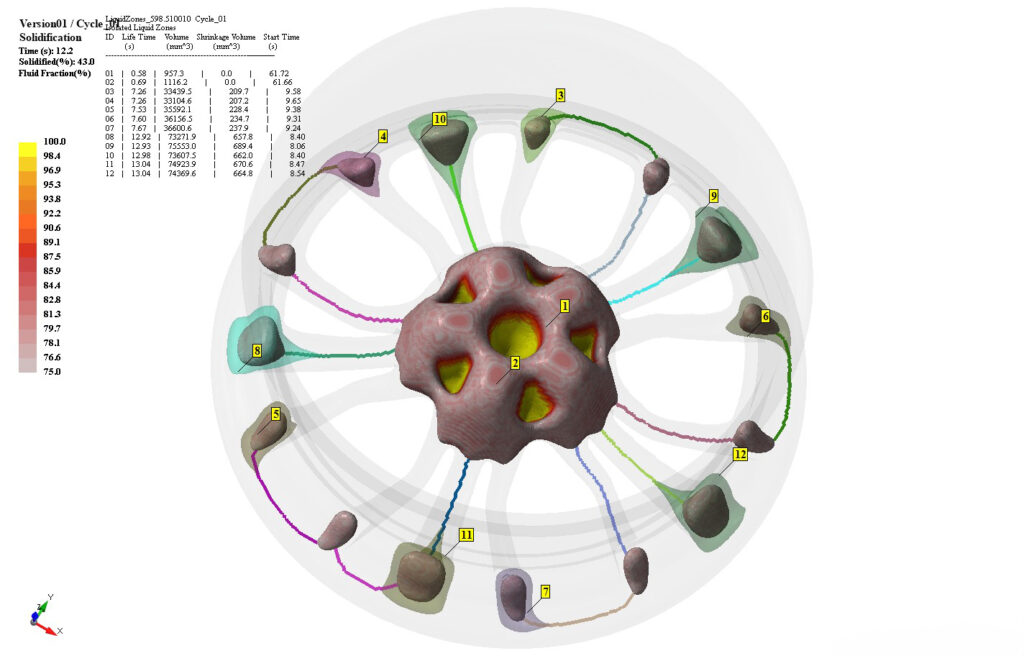

This cutting edge simulation platform is built to eliminate trial-and-error in casting design. With high-speed solvers running on both CPU and GPU, simulations run significantly faster than with conventional tools — enabling rapid iteration and shorter development cycles. The software supports a wide range of casting methods, including low-pressure die casting, gravity die casting, and sand casting. It also includes real-time 3D visualization, CAD-independent geometry handling, and automated setup features — making the entire simulation process more efficient.

Geometry optimization that makes a difference

One of its most powerful features is advanced geometry optimization. The system automatically detects isolated zones, refines mesh in critical areas, and improves directional solidification — helping prevent defects such as shrinkage and misruns. You can even make geometry changes mid-simulation and continue without starting over.

Built for Casting Professionals

NovaCastCAD is ideal for casting engineers, product designers, and foundries looking to shorten development time, reduce defects, and improve casting quality. It supports a wide range of casting processes and is well suited for industrial applications where high demands are placed on precision, efficiency, and simulation speed.