ATAS MetStar

ATAS MetStar is an easy to use, adaptive metallurgical process control system for analyzing, stabilizing and optimizing the metallurgical production process. ATAS MetStar is the fundamental tool for a foundry to improve quality, control and increase stability of the metallurgical parameters. The result is reduced scrap rate, less energy consumption and a greener planet.

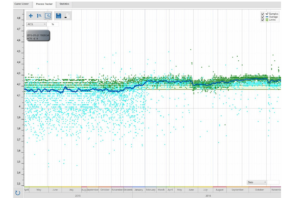

ATAS (Adaptive Thermal Analysis System) MetStar is a flexible metallurgical process control system for analyzing, stabilizing and optimizing the metallurgical production process. The system has been developed from a metallurgical point of view, based on years of foundry experience both from NovaCast’s own personnel but also customers’ day-to-day challenges. The system is used to create routines and rules for developing a lean production method.

The analyze phase consists of analyzing a number of physical samples of a specific alloy or melt quality and find the best practice. The stabilizing phase consists of extracting data from the analysis and defining the unique fingerprint for a specific desired quality to secure the best practice. The optimizing phase is the final stage of our process where fine tuning and improving the best practice takes place. This leads to a process with less variations and a stable quality and results in reduced scrap rate, less energy consumption and a greener planet. ATAS MetStar predicts the possible risk for defects in the castings such as; micro shrinkage porosity, macro shrinkage porosity, chill tendency (cementite), inverse chill tendency, oxygen content and mechanical properties.

The latest release of ATAS MetStar 11 (June 2025) introduces two major innovations: support for the new ATAS DAD device and an enhanced MasterMind module with integrated spectrometer data.

ATAS DAD enables high-resolution, 8-channel data acquisition at 5 Hz, featuring synchronized control and seamless integration into the ATAS MetStar interface. All algorithms and visualizations have been updated to support this expanded input, making it ideal for modern multi-cup thermal analysis and next-generation process monitoring.

MasterMind, already a powerful tool for identifying correlations between thermal parameters and process outcomes, now incorporates spectrometer data. This enhancement allows users to uncover meaningful relationships between chemical composition and thermal behaviour, automatically generating user-defined equations for improved predictions and deeper insights into material performance.

Additional highlights in ATAS MetStar 11:

· Enhanced Usability in Curve Analyzer: Now supports multi-alloy comparisons and highlights active user-defined values.

· ATAS One monitoring license: Replace traffic indicators with enhanced visual representations tailored to where they are most needed.

· Unified Gauge Results View: All results now accessible in a single tab.

· Dynamic Inoculation inside the Ductile Iron Module: Enhanced automation to minimize human error.

· Calculate best fit for TEHigh: Now available for grey samples without recalescence.

· New user equation: Estimate silicon (Si) from TL in white samples.

· User-defined equations in Curve Comparison: Real-time gauge results included.

· Process advice history: Improved traceability and process optimization.

· Cloud-compatible database backup: Secure and accessible system backups.

>> Are you a student?

Click here to learn more about our university offer.

In need of a charge calculation system?