Knowledge library

7 min read

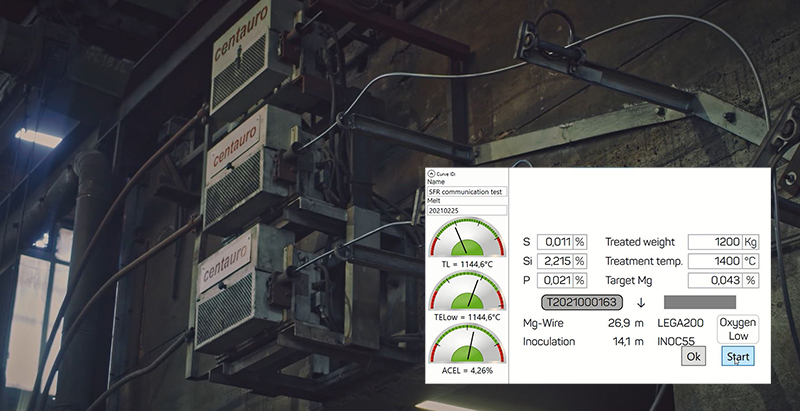

Determination of feederless casting limits by thermal analysis in cast iron.

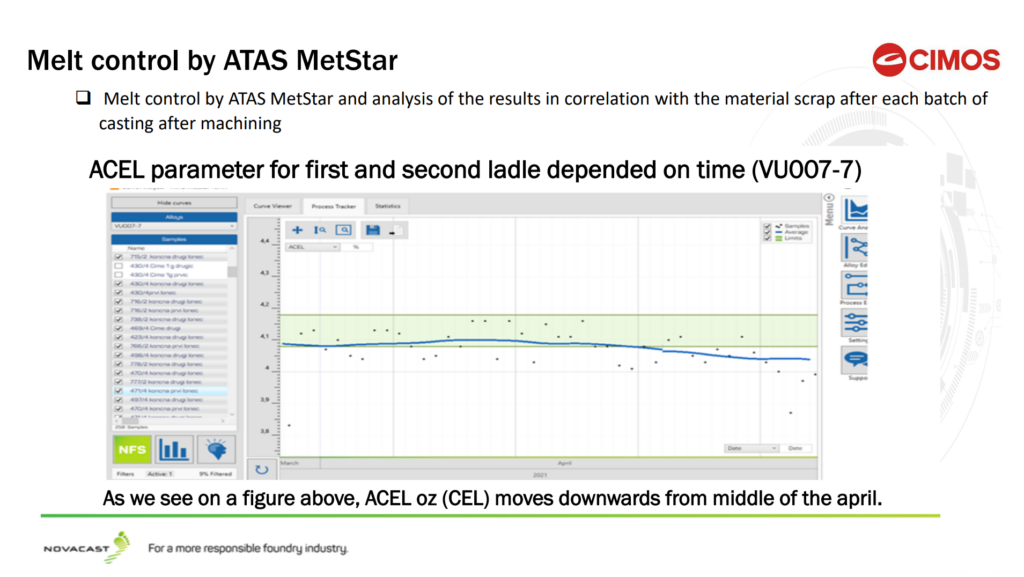

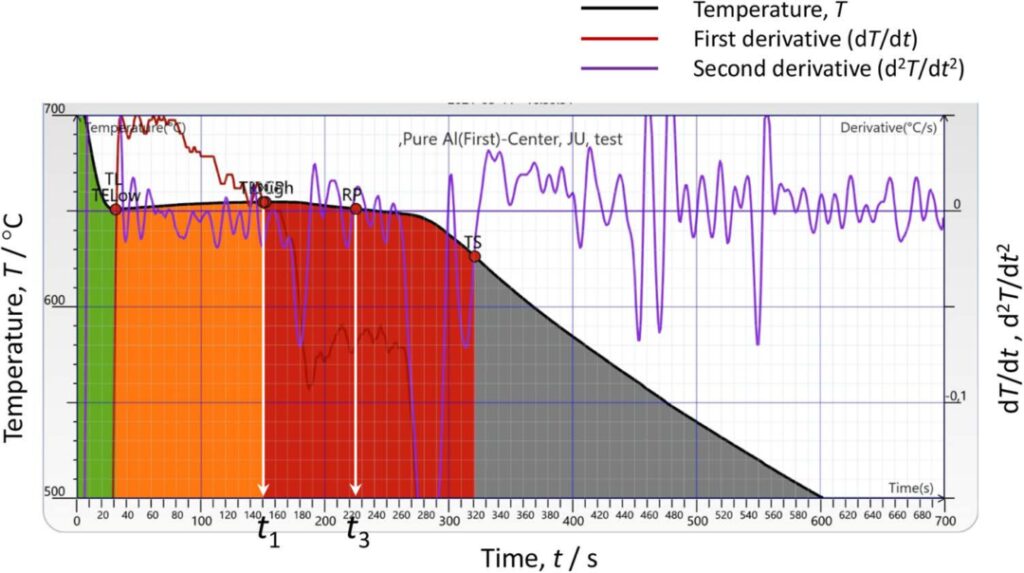

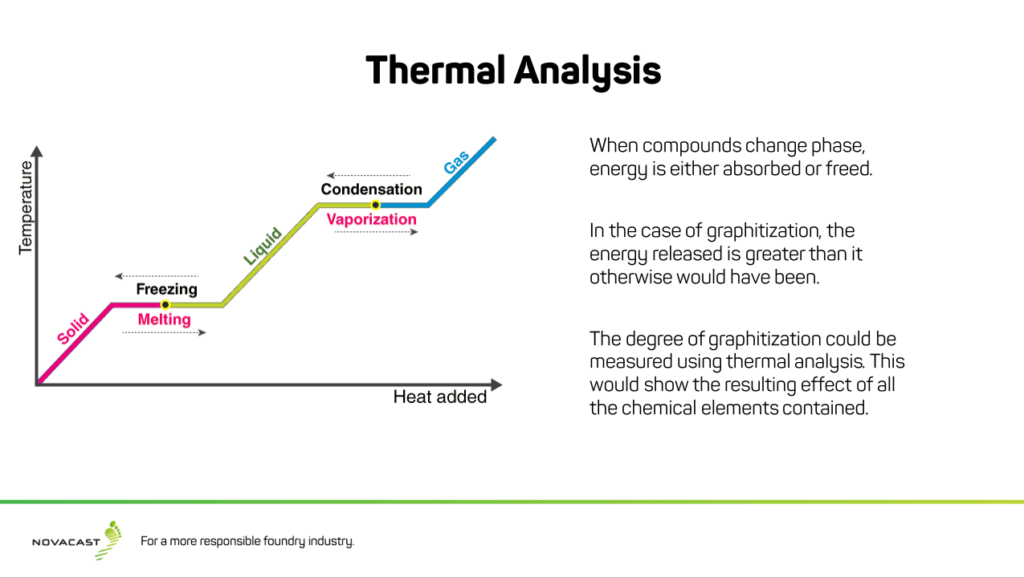

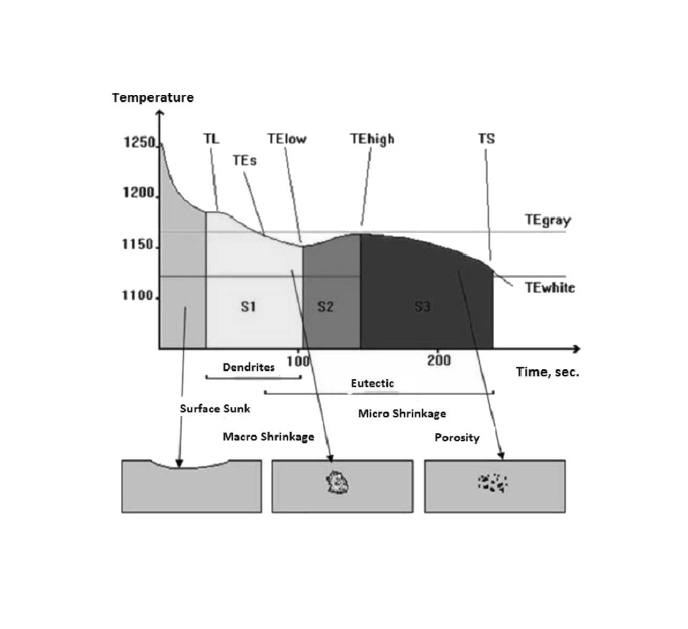

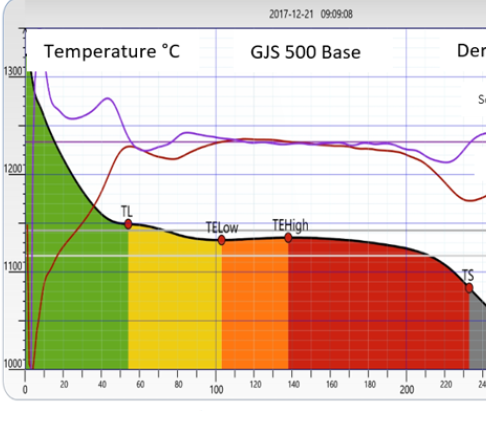

In this study the determinations of melt quality was carried out by thermal analysis of ductile iron. The aim of the study was to determine the limits of feederless casting after the determination of inoculation quality in cast iron.

+10 min read

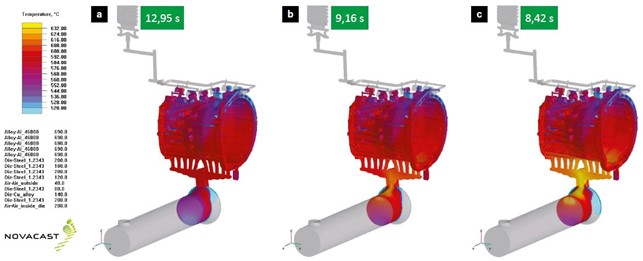

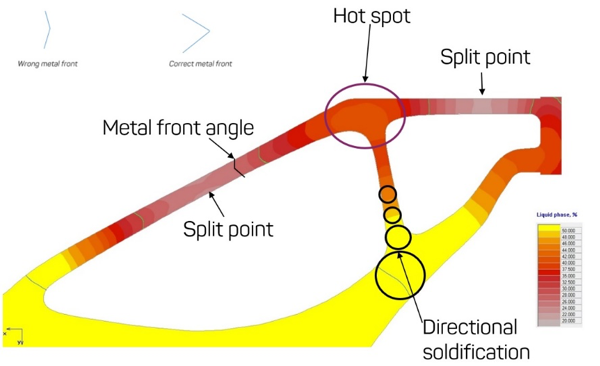

Increasing precision and yield in casting production by simulation of the solidification process

The conducted work shows and confirms how thermal analysis of grey and ductile iron is an important source for calculating metallurgical data to be used as input to increase the precision in simulation of cooling and solidification of cast iron.

5 min read

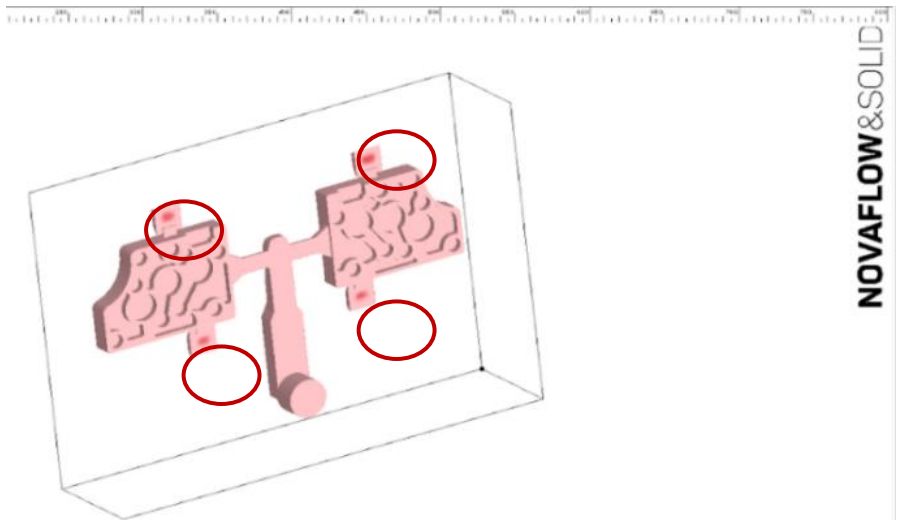

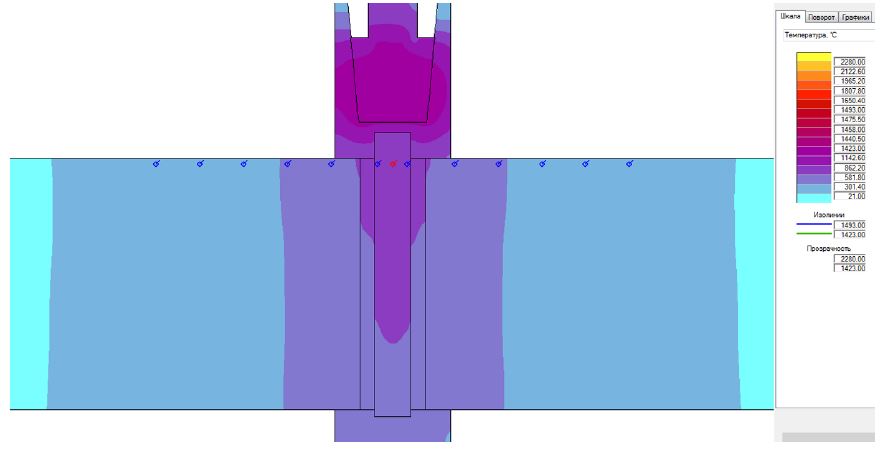

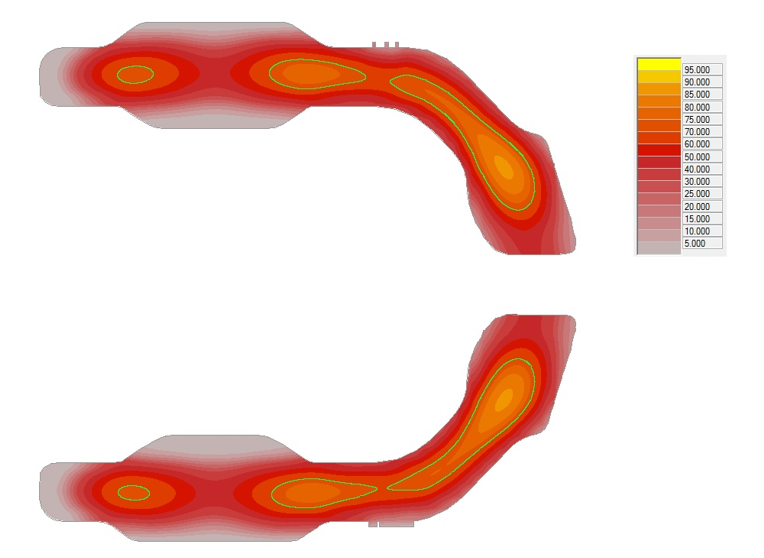

Parameter and casting optimization with simulation-driven casting design.

Castings are becoming lighter, stronger and increasingly defect-free, but there remains room for improvement. The higher demands for lower weights and higher quality challenges us to change how to design and produce castings.

5 min read

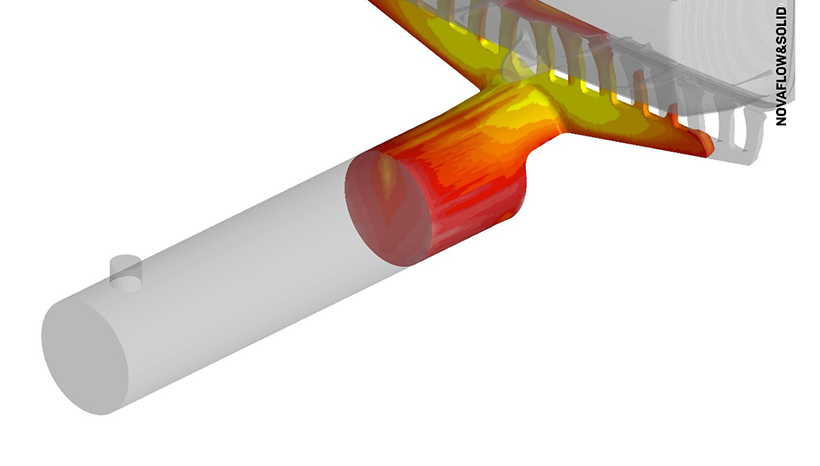

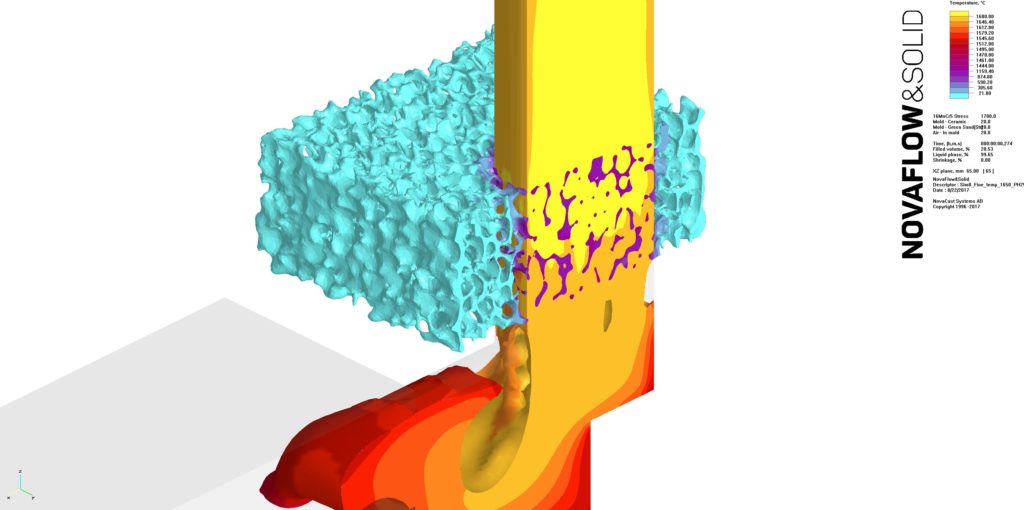

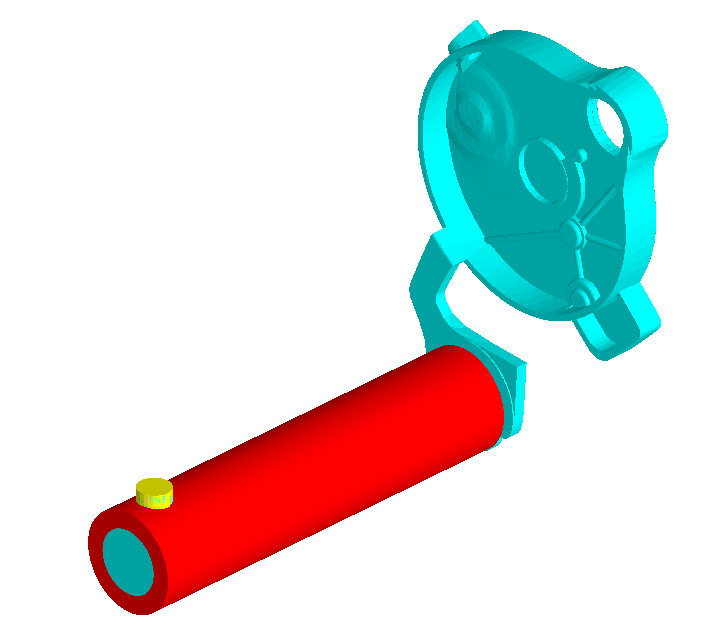

Simulating high pressure die casting with full process

NovaFlow&Solid is using something called Multi-mesh which means that we can use different size of mesh for the whole calculation domain during certain times in the simulation making it possible to simulate the gravity pouring of chamber followed by the piston movement just in minutes. In this way you can concentrate the simulation time on the most important part of the simulation the: filling of the casting cavity.